Beyond the Panels: What's Actually Involved in Professional Solar Preventative Maintenance?

- gcarbajal276

- Jan 27

- 5 min read

You made a significant investment when you installed solar panels on your property. Perhaps you were told they'd last 25 years with minimal upkeep. Maybe you assumed the system would simply run itself indefinitely. And while solar technology is remarkably reliable, the reality is that "set it and forget it" doesn't quite apply if you want to maximize your return on investment.

Professional solar preventative maintenance is about far more than hosing down your panels once a year. It's a comprehensive approach that involves electrical inspections, equipment diagnostics, structural assessments, and performance analysis, all designed to catch small issues before they become expensive problems.

So what actually happens during a professional maintenance visit? Let's pull back the curtain.

Why Solar Systems Need Regular Attention

Solar panels themselves have no moving parts, which contributes to their longevity. However, your solar system is more than just the panels on your roof. It includes inverters, wiring, mounting hardware, junction boxes, and monitoring equipment, all of which are exposed to the elements 24/7, 365 days a year.

Temperature fluctuations cause materials to expand and contract. UV exposure degrades certain components over time. Dust, pollen, bird droppings, and environmental debris accumulate on panel surfaces. Connections loosen. Seals wear down.

Studies indicate that poorly maintained solar systems can lose 10-25% of their efficiency over time. For a commercial installation, that efficiency loss translates directly into money left on the table, or worse, unexpected system failures that disrupt your operations.

The Anatomy of a Professional Solar Maintenance Check-Up

When a licensed electrical contractor conducts a preventative maintenance visit, they're looking at your entire system holistically. Here's what that process actually involves:

Visual and Structural Inspections

The first step is a thorough visual assessment of your solar array. Technicians examine each panel for physical damage, cracks, chips, discoloration, hot spots, or cloudiness that could indicate delamination. Even hairline cracks can allow moisture infiltration, which compromises panel performance and longevity.

Beyond the panels themselves, professionals inspect:

Mounting systems and racking for signs of corrosion, rust, or structural fatigue

Roof penetrations and flashing to ensure waterproof seals remain intact

Hardware and fasteners throughout the installation

Here's something most property owners don't realize: temperature swings cause bolts and screws to loosen over time. A professional technician uses calibrated torque wrenches to verify that all mounting hardware meets manufacturer specifications. Loose components don't just affect performance, they can become safety hazards during high winds.

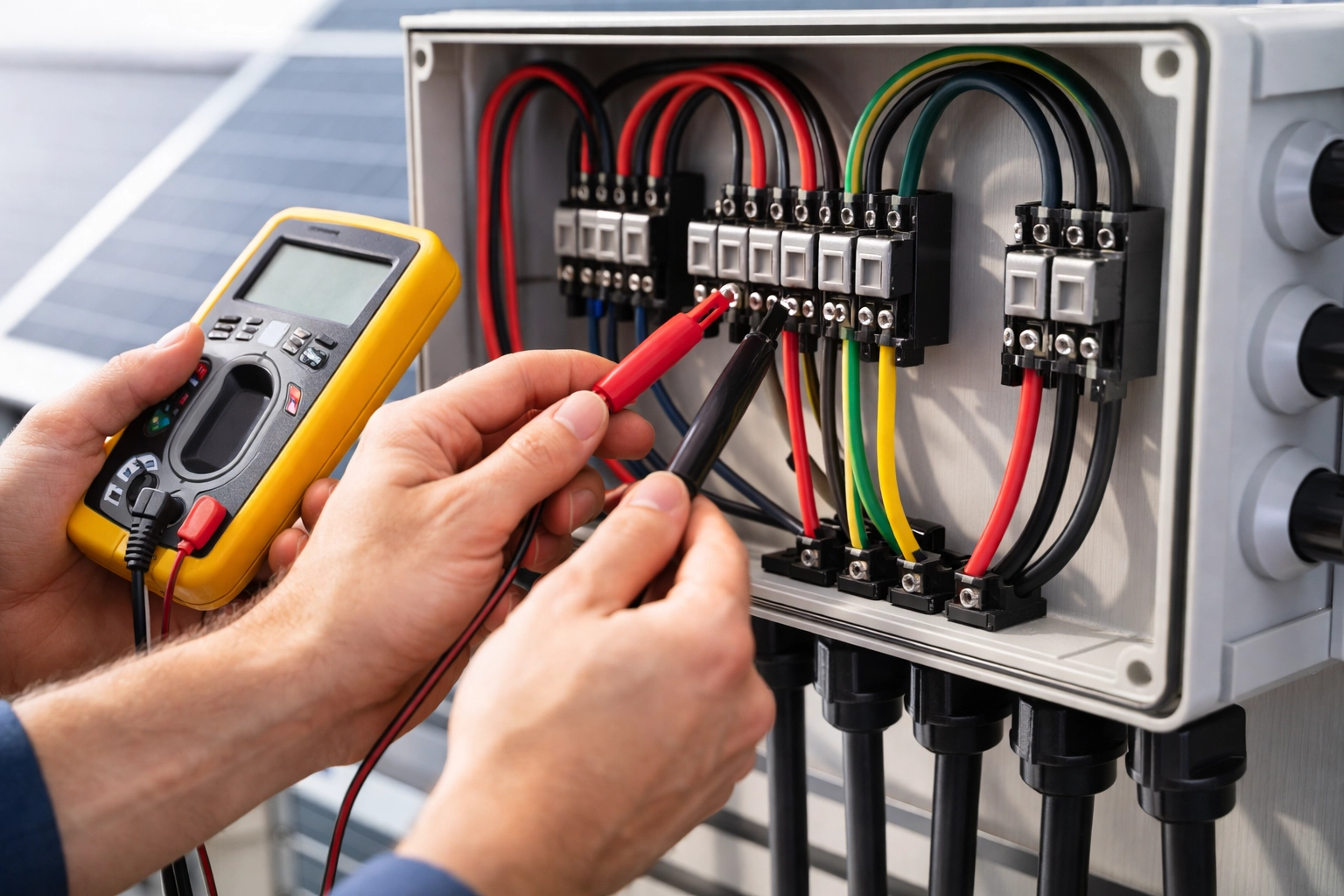

Electrical Connection Checks

This is where having a licensed C-10 electrical contractor makes all the difference.

Your solar system contains dozens of electrical connections, from panel-to-panel wiring to combiner boxes to your main electrical panel. Each connection point is a potential failure point. Loose connections create resistance, which generates heat, reduces efficiency, and in worst-case scenarios, poses fire risks.

During a professional inspection, technicians:

Verify all wire connections are secure and properly torqued

Check for signs of corrosion, heat damage, or arcing

Inspect conduit and wire protection for damage or degradation

Test grounding systems to ensure they meet code requirements

Examine junction boxes and combiner boxes for moisture intrusion or pest damage

In my experience, electrical issues are among the most common, and most overlooked, problems in aging solar installations. A connection that looked perfect at installation can degrade significantly after years of thermal cycling and environmental exposure.

Inverter Health Assessment

Your inverter is the hardest-working component in your solar system. It converts the DC power generated by your panels into usable AC power, and it does this continuously during daylight hours. Most inverters have an expected lifespan of 10-15 years, significantly shorter than the panels themselves.

Professional maintenance includes:

Performance verification to confirm the inverter is operating within normal parameters

Error code analysis to identify any warning messages or fault conditions

Ventilation checks to ensure cooling systems are functioning properly

Firmware updates when applicable to optimize performance

Inverter problems often develop gradually. You might not notice a 5% efficiency drop, but over a year, that adds up. Professional monitoring catches these subtle declines before they become major issues.

Panel Cleaning Done Right

Yes, cleaning matters: but it's not as simple as grabbing a garden hose.

Professional cleaning involves:

Using purified or deionized water to prevent mineral deposits

Soft brushes or squeegees that won't scratch panel surfaces

Cleaning during appropriate times (early morning or evening) to avoid thermal shock

Addressing stubborn deposits like bird droppings or tree sap that can cause hot spots

For commercial installations, the stakes are higher. A large rooftop array covered in a thin layer of grime might be operating at 85% capacity instead of 95%. Multiply that loss across hundreds of panels, and you're looking at significant revenue impact.

Performance Monitoring and Analysis

Modern solar systems generate tremendous amounts of data. Professional maintenance includes analyzing this data to identify:

Production anomalies that indicate underperforming panels or strings

Degradation rates that exceed normal expectations

Shading issues from new obstructions like tree growth or neighboring construction

System settings that may need recalibration for optimal output

This data-driven approach allows technicians to pinpoint problems that wouldn't be visible during a physical inspection alone. A panel might look perfectly fine but consistently underperform its neighbors: something only monitoring data reveals.

The Value of Preventative Maintenance Programs

One-time inspections are helpful, but preventative maintenance programs deliver the greatest value. Here's why:

Consistency matters. Regular inspections create a baseline understanding of your system's normal performance, making it easier to spot deviations early.

Scheduling is handled for you. With a maintenance program, you don't have to remember to book annual service: it's already on the calendar.

Priority response. Program members typically receive faster response times when issues arise between scheduled visits.

Cost predictability. Rather than unexpected repair bills, you have a known annual maintenance cost you can budget for.

At Current Electric Inc., our preventative maintenance programs are designed specifically for the demands of Southern California's climate. With over 35 years of experience as a licensed C-10 electrical contractor, we understand what it takes to keep solar systems performing at their peak in our unique environment.

When to Schedule Professional Maintenance

Most industry experts recommend annual professional inspections for solar systems. However, you should consider more frequent evaluations if:

Your property is in an area with severe weather events

You've experienced unusual production drops

Your system is approaching or past the 10-year mark

You've had any roof work or construction near your array

You notice visible damage or debris accumulation

After significant weather events: Santa Ana winds, unusual storms, or extreme heat waves: a post-event inspection can identify damage before it compounds into larger problems.

Trust Your Investment to Qualified Professionals

Not all solar maintenance providers are created equal. When selecting a maintenance partner, look for:

Proper licensing (in California, a C-10 electrical contractor license)

Extensive experience with solar installations specifically

Comprehensive service offerings that go beyond basic cleaning

Strong local reputation and verifiable references

Current Electric Inc. brings over three decades of electrical expertise to every solar maintenance project. Our team understands the technical complexities of photovoltaic systems and the electrical infrastructure they connect to. We don't just clean panels: we ensure your entire system is operating safely and efficiently.

Protect Your Investment Today

Your solar system represents a significant financial commitment. Professional preventative maintenance protects that investment, maximizes your energy production, and extends the operational life of your equipment.

Don't wait for problems to announce themselves through reduced production or system failures. Proactive maintenance is always more cost-effective than reactive repairs.

Ready to discuss a preventative maintenance program for your solar installation? Contact Current Electric Inc. today to schedule a comprehensive system evaluation. Let's make sure your solar investment delivers the returns you expected( for decades to come.)